Breakthroughs in implant technology change how dentists restore missing teeth. Dental implant innovations in 2025 introduce advanced materials, digital precision, and faster procedures to improve patient outcomes. These advancements help clinics offer more durable, comfortable, and functional restorations with shorter recovery times. Implant success rates increase as researchers develop solutions that strengthen bone integration and resist infections.

New technologies enhance customization and long-term performance. Smart monitoring, 3D printing, and nanotechnology coatings bring new possibilities to implant dentistry. Here are the latest innovations shaping the future of implant treatments.

Smart Dental Implants for Real-Time Monitoring

Implants now feature embedded sensors that track pressure, temperature, and bone healing. These smart devices send real-time data to dentists, allowing them to detect potential failures before symptoms appear. Early intervention prevents complications, reducing risks associated with poor healing or excessive stress on the implant. Patients also benefit from personalized insights into their oral health.

Wireless technology integrates with mobile apps, providing instant updates on implant stability. Dentists monitor healing remotely, reducing unnecessary visits. This advancement increases implant longevity and ensures optimal function. Smart monitoring helps clinics refine treatment plans based on real patient data, improving success rates.

3D-Printed Implants for a Precise Custom Fit

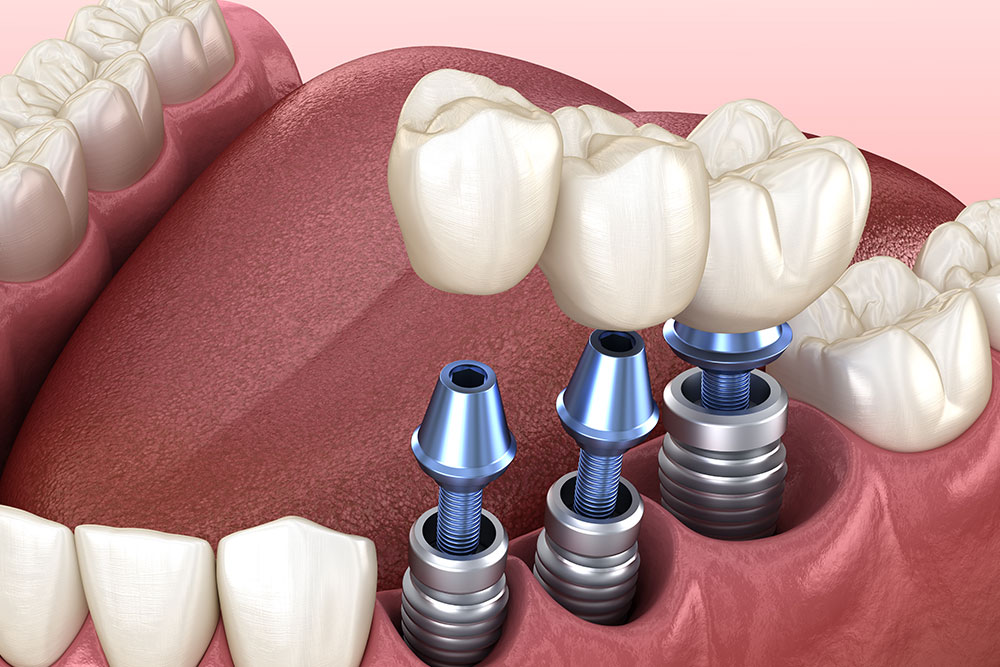

Digital dentistry improves implant accuracy by using 3D printing to manufacture patient-specific restorations. Unlike traditional methods, this process creates implants with exact dimensions that match a patient’s anatomy. The precise fit reduces pressure on surrounding tissues and enhances long-term stability.

Advanced printing materials mimic natural bone properties, promoting better fusion with surrounding tissue. Dentists design and print implants in-house, cutting down production time. Faster manufacturing means patients receive their restorations sooner without compromising quality. The ability to customize implants improves comfort and function while reducing the need for adjustments.

Biomimetic Materials for Better Bone Integration

New materials mimic natural bone structure, helping implants integrate more effectively. These biomimetic coatings encourage bone cells to grow around the implant, creating a stronger connection. Better integration reduces the risk of implant failure and shortens healing time.

Surface treatments enhance how bone interacts with the implant. Calcium phosphate coatings and bioactive glass stimulate bone regeneration. Some materials even release antimicrobial agents to prevent infections. These advancements give dentists more reliable options for patients with low bone density or slow healing.

Immediate Loading Implants for Faster Treatment

Same-day implants allow patients to leave the clinic with a functional tooth immediately after surgery. Traditional implants require months of healing before placing the final restoration, but immediate loading techniques eliminate this waiting period. The implant anchors securely in the bone, supporting a temporary crown right away.

New surface treatments speed up osseointegration, ensuring the implant remains stable under chewing forces. Dentists achieve predictable results with digital planning and guided placement. Immediate loading improves patient satisfaction by reducing treatment time while maintaining long-term success.

Nanotechnology Coatings to Improve Implant Success

Nanotechnology enhances implant surfaces at a microscopic level to increase stability and healing speed. These coatings create a rough texture that encourages bone attachment, leading to stronger integration. This method improves outcomes for patients with low bone density or slow healing.

Antibacterial coatings reduce infection risks, preventing complications that lead to implant failure. Some nanomaterials also release controlled amounts of medications to support healing. These innovations make implants more resistant to biological challenges, ensuring a higher success rate for long-term restorations.

Innovative Dental Product Manufacturing at Next Dental Lab

Precision and innovation define our approach to innovative dental implant development at Next Dental Lab. We use advanced materials and digital technology to improve patient outcomes and treatment success. Real-time monitoring solutions give dentists valuable insights into implant stability, allowing them to address concerns before they become problems. Our expertise in custom implant manufacturing guarantees a perfect fit for each patient, reducing discomfort and ensuring long-term performance.